What is Shot blasting machine?

The shot blasting machine is essential across various metal industries, by centrifugal force to blasting steel grit and shot-steel to effectively eliminate surface stains, rust, and ensure product surface integrity.

Shotblasting surpasses alternative surface treatment techniques in terms of speed and effectiveness, making it the preferred choice due to its exceptional metal surface cleaning (WPC) capabilities and environmentally friendly nature. Additionally, this blasting method finds application in marble & concrete treatment as well.

Two different techniques: Shot blasting & Sandblasting:

Shot Blasting:

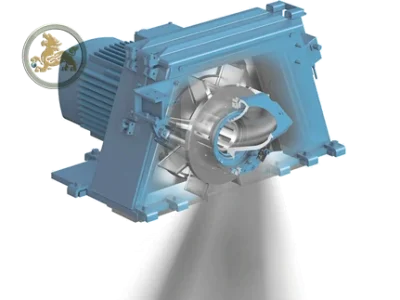

The shot blasting machine utilizes centrifugal rotating turbine blades to propel high-speed steel media (such as steel, copper, aluminum, or other high-velocity beads) onto the surface at a specific angle. This process serves multiple purposes, including deburring, desanding, cleaning, and strengthening the surface of castings, as well as removing rust, paint, or other coatings.

The selection of abrasive media for shot blasting depends on the particular task at hand. In most cases, metallic materials are the preferred choice due to their effectiveness and versatility in achieving the desired results.

SandBlasting:

The sandblasting process involves the pneumatic acceleration of the media using compressed air, eliminating the need for a centrifugal turbine. This allows users to exert control over the blast direction through a specially designed nozzle.

In certain specialized applications, a wet blasting machine is employed, where an abrasive media-water mixture is utilized. This mixture enhances the efficiency of the sandblasting process, albeit at an increased cost.

For most cases, dry or free-flowing abrasive media is consumed during the sandblasting operation. This ensures optimal efficiency while minimizing expenses.

Function of Shot blasting machine:

Shot blasting is primarily used to remove burrs, diaphragms, and rust from steel surfaces, particularly during high-volume metal production processes. These surface imperfections can significantly impact the integrity and appearance of the object. Shot blasting creates a rough surface profile, increasing the adhesion of coatings and strengthening the workpiece.

Additionally, shot blasting can fully open the capillary pores on concrete surfaces, allowing sealants or binders to penetrate deeply. This process helps reveal concrete defects in advance, ensuring thorough treatment and preparation.

The type of shot abrasive media:

- Steel grit

- Copper shot

- Zinc shot

- Cut wire shot

- Steel cut wire

- Aluminum oxide

- Steel pellets

Different from shotblasting and shot-peening:

Shot blasting machine primarily serves as a surface finishing process, aiming to modify parts’ surfaces by smoothing rough areas, reshaping contours, or removing contaminants. Its main purpose is to prepare the surface for subsequent operations, such as painting or coating, to improve adhesion and smoothness.

Shot-peening machine focus on the process of “peening.” This technique is aimed at improving the material properties of the surface by increasing compressive stress. The primary objective of shot peening is to enhance the workpiece’s strength and durability by mitigating tensile stress and improving resistance to fatigue and cracking.