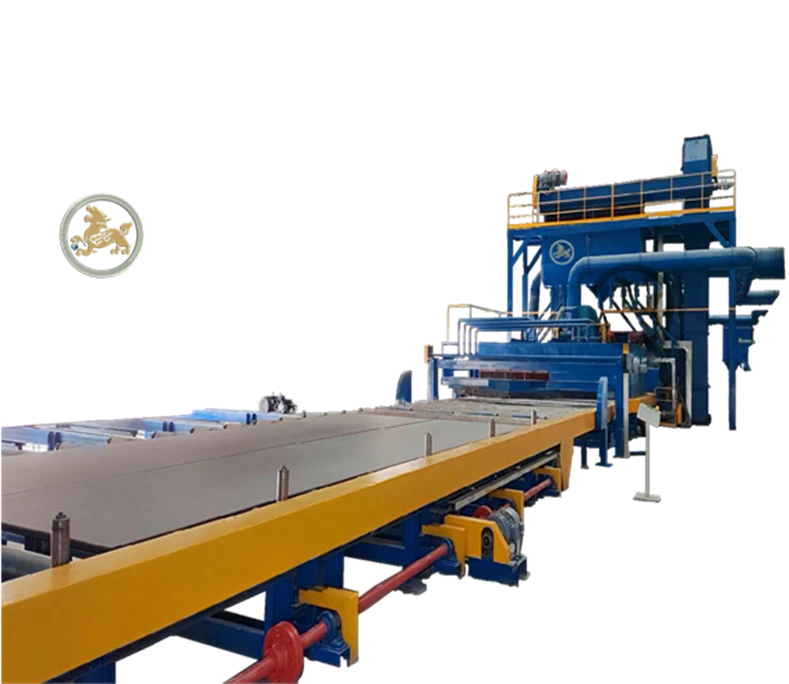

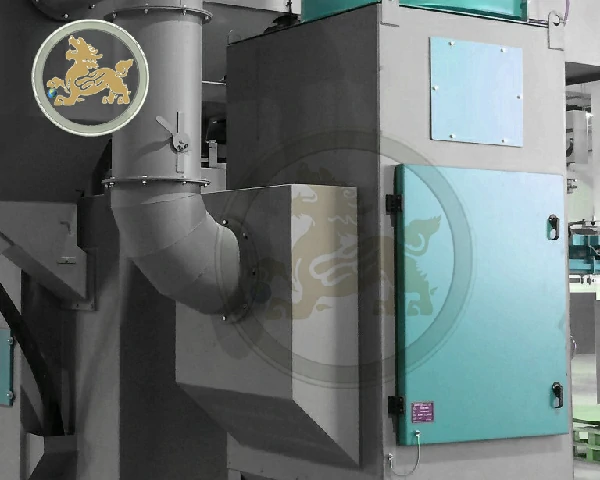

Steel Plate shot blasting machine

Preservation line: Shot blasting & Painting

shot blasting and painting

The surface treatment system of the preservation line comprises automatic shot blasting, painting lines, booths, and in-line drying ovens for treating sheets, profiles, structures, and strips. It features continuous horizontal roller conveyors to process parts efficiently, ensuring high productivity and cost-effectiveness by minimizing unnecessary part handling.

The key feature of the preservation line is the roller conveyor shot blasting machine which equipped with sweeping system and fan blowing system for remove the media left on the top surface.

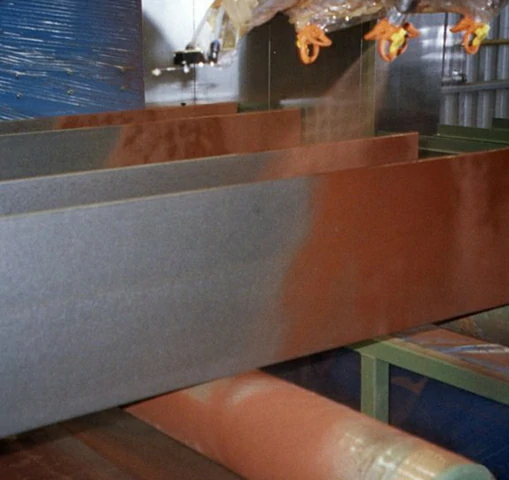

Following components like the pre-heater facilitate the preparation of damp and cold steel parts for the shot blasting process, where work pieces are cleaned and descaled using high-performance shot turbines. Subsequently, the parts move through an automated paint system for dual-sided coating before entering the heating chamber and last process is gas removal system.

Features & Advantage:

- PLC control minimizes labor expenses.

- Guarantees homogeneity of surface cleaning.

- High production volume, with minimum operating cost.

- Durable wheel turbines with high-chrome, wear-resistant material and multi-grade projectiles.

- Compact design, user-friendly operation, low maintenance, and excellent reputation.

- Environmentally friendly with no pollution.

Applications:

- Plate: Achieving smooth sheet surfaces for painting, coating, cutting, welding, etc.

- Metal construction works: Preparing surfaces for welding, cutting, drilling, and other operations.

- Pipes: Surface cleaning for painting, coating, drilling, welding, etc.

Characteristics of shotblasting & painting line:

Airless Shot Wheel Turbines:

Shot turbines: Variable from 2200 to 3800 RPM for maximum abrasive velocity fitted with optional electronic inverter control; Upgraded wearing-resistance protective liners with low working noise & vibration;

Blade: Cast from unique wearing resistant alloy for extensive life with access design for easy change;

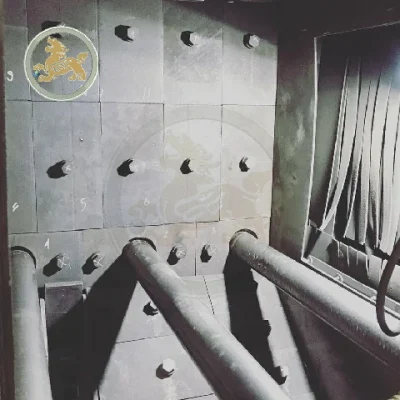

Durable Shot Blasting Chamber:

Shot blasting room: The shot blasting room is designed using CAD to achieve optimal blasting angles and distances. It is constructed with durable profiles and 10mm plates, while the direct-blasting hot area utilizes upgraded manganese casting steel with 35-45 HRC for enhanced wearing resistance.

Entrance/Exit: The input and output areas are sealed with rubber bands, and a labyrinth structure is implemented to prevent abrasive leakage.

Roller conveying system:

Rollers: The roller conveyors are equipped with manganese liners to extend their lifespan. The bearing support is designed in a labyrinth shape to prevent leakage of the steel media.;

Capacity: The rollers which self-rotate speed variable controlled, and the lifting capacity can reach 1,000 – 3,000kgs/m;

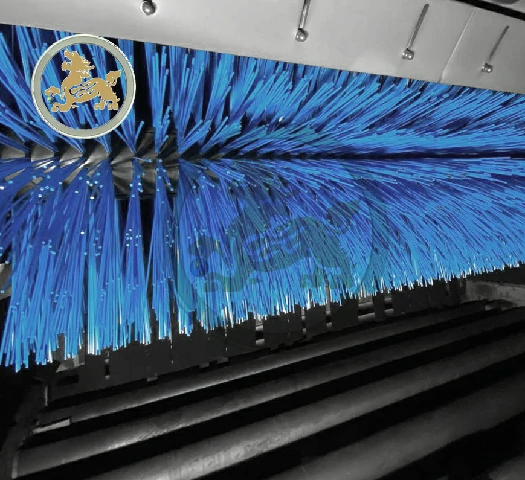

Additional media-remove system:

Scrapper system: Scrappers’ height adjust with the PLC and HMI interlock control;

Brush sweeping system: The continuous brush sweeping, made of high-performance Nylon, can be adjusted in height based on the sheet’s requirements;

Fan blowing system: The blowing-off station features a high-pressure fan, and the direction of the blowing nozzle can be adjusted as needed.

Painting & Heating room:

Painting: A sensor of the product size and entry; The paint is applied from above and below with eight paint guns; Automatic detection to start a painting by each individual paint gun;

Heating: Prior to entering the shot-blasting and afterward of painting; the Circle of heating airflow; Exit of harmful hazard air;

Recycle of abrasive material:

Elevator: The elevator raises the abrasive to the separator, utilizing a bucket made of foundry casting, while a tension device prevents belt slippage.;

Separator: The separator incorporates DISA & Pangborn technology, enabling the separation of abrasive into three classes with an impressive efficiency rate of 99.5%;

Dust collect system:

Cartridge filter: The dust collector filters utilize a cartridge-type system, boasting an exceptional efficiency rate of 99.9% and offering hassle-free replacement of cartridge filters;

Noise: Silencer to minimize of noise reach of 90dB;

Electrical Control system:

Electrical elements: All voltage adopts, overload protection on all motors, PLC automatic control & HMI (Human Machiner Interface) to monitor all elements;

Safety: The operation features a safety interlock system, while the control cabinet is protected with IP65 rating;