Shot blasting machine price

What is the factors effect of the price of the shot blasters?

Shot blasting machine price

Shot blasting machines use abrasive by centrifugal force that plays a crucial role in the manufacturing and metalworking sectors, providing essential surface preparation for diverse applications, including cleaning, deburring, and improving the finish on metal and marble components.

These blasting machines are commonly utilized for various surface finishing treatment processes, such as cleaning, descaling, and shot-peening, within the metalworking industry and related versatile applications include abrasive blasting to prepare and clean metals, stones and other materials, as well as shot peening and cleaning of metal parts like castings, heavy metals, aerospace, automotive, construction, infrastructure development, shipyard, and rusted components to ensure high-quality surface finishes for afterward of surface painting and coating.

The growing demand for shot blasting methods in the metal industry, driven by increasing industrial activities, infrastructure development, and the need for high-quality surface finishes, is projected to drive the expansion of the global shot blasting machine market, which was valued at USD 1.24 billion in 2022 and is expected to reach USD 1.87 billion by 2030.

The cost of shot blasters can be affected by numerous elements, including:

1. The blasting type: Based on technology with wheel blasting, air blasting and wet blasting.

The wheel blasting, generally, is an automatic shot turbine for a large capacity and is usually expensive that work with most applications like automotive and metalworking for tasks such as cleaning and surface finishing preparation.

The air blasting machine can work automatically and manually, the working station more widely indoor enclosed blasting room or outdoor blasting work at the open air, the applications with large size or sophisticated shapes from electronics, medical and aerospace equipment manufacturing sectors.

The wet blasting machine generally work in the open air, because the abrasive blasting with water, so during of blasting do not have pollution and environmental-friendly; The application is especially for the mobile site like the walls to remove graffiti, water pool and some small capacity blasting industries; Also the invest is generally the lowest.

2. Workpieces size and Blasting capacity:

Shot blasters with larger dimensions and greater shot turbines capacity are generally more expensive than their smaller shot blasting machines.

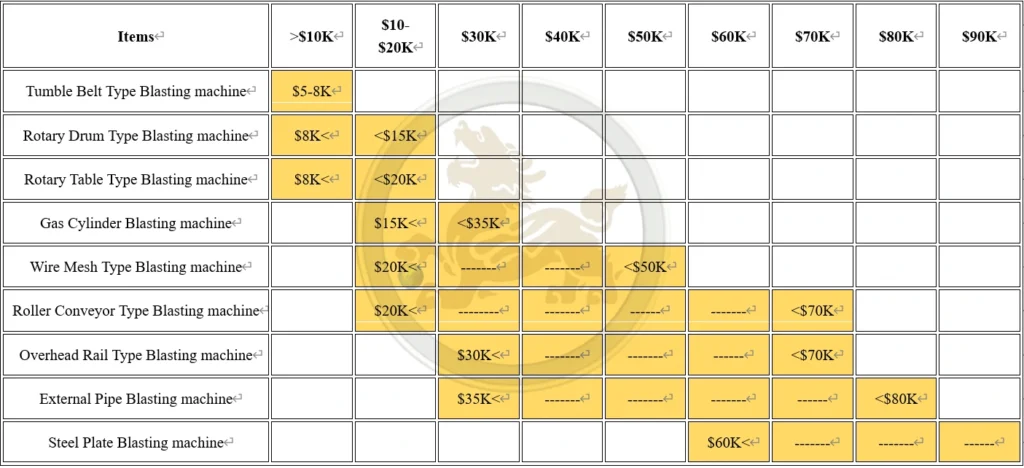

Based on machine type, the market is segmented into tumble belt shot blasting machine, hanger type shot blasting machine, roller conveyor shot blasting machine, and turntable type shot blasting machine.

- The market is currently being led by the tumble belt shot blasting machine, expected to experience the highest growth rate due to its low energy consumption and widespread application across different industry sectors without requiring a foundation.

- The spinner hanger type shot blasting machine offers diverse loading capacities, various blast wheel setups, and different levels of automation to ensure effective cleaning of intricate components.

- The rotary-table type shot blasting machines are specifically crafted for the cleaning, descaling, and surface preparation of large or flat workpieces that can be positioned on a rotating table.

- The roller conveyor type shot blasting machine is designed for the automated, continuous flow of workload such as the beams, profiles, sheet and steel structures; The best benefit is combined with the afterward of painting or coating line.

3. Power and Blasting performance:

Higher performing shot blasters, characterized by superior shotblast velocity and coverage, often with a higher cost.

4. Brand of parts and Reputation of manufacturer:

Well-established and trusted brands in the shot blasting industry typically price their equipment higher due to their recognized quality and dependability. (The brands of the motors can be Siemens/ABB, Reducer with SEW, the PLC with Siemens, the electrical parts with Schneider etc.)

5. Material quality and Durability:

Shot blasters constructed from top-grade materials and designed for long-lasting durability can have a higher price point.

6. Features and Automated technology:

Cutting-edge features and technological advancements, such as automated controls, dust collection systems, and adjustable settings, can lead to a price increase.

Based on the mode of operation, the market is segmented into automatic and manual.

- The automatic type blasting equipment dominates the market also with more expensive cost as automated shot blasting machines are generally more efficient and faster than manual systems that can process a large number of workpieces consistently and continuously.

- The manual segment is offering greater flexibility allowing operators to adapt to various work pieces and surface conditions, low investment.

7. Accessories and Attachments:

Supplementary accessories and attachments like unique shot wheels or varied abrasive media options can escalate the overall cost.

8. Maintenance and operational costs:

Regular maintenance is essential for ensuring the longevity of the equipment. Machines that are easier to maintain may have a higher upfront cost but can save businesses money in the long run by minimizing downtime and repair expenses.

9. Market Demand and Competition:

The interplay of supply-demand dynamics and competition among manufacturers can influence shot blasters’ pricing.

10. Warranty and Support:

Shot blasters with extended warranty periods and comprehensive customer support services can be priced higher due to the added value they offer.

Advanced shot blasting machines often require a substantial upfront investment, posing a barrier for smaller enterprises or those with budget limitations. Apart from the initial cost, operational and maintenance expenses, such as abrasive materials, energy usage, and regular upkeep, further add to the financial burden. These ongoing costs can prove challenging for businesses, potentially hindering the widespread adoption of this equipment.

Moreover, the average cost required for such a machine is around USD 5,000 to USD 30,000.

While considering the price of shot blasters, it’s important to weigh these factors to ensure that the selected equipment satisfies specific requirements and delivers the best value for the intended application.