Sheet tunnel shot blasting machine

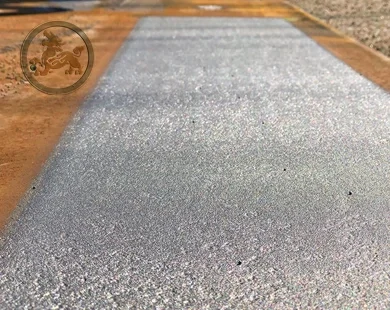

Tunnel shot blasting machine for plate is efficiently prepare long and flat metal sheets and components by descaling, de-rusting, paint removal, deburring, and surface preparation for welding, cutting, machining, or burning operations.

The automatic continuous sheet shot blast machine feature motorized roller conveyors with adjustable feed speed and offer options of horizontal or vertical roller track conveyors for seamless material transfer. Strategically positioned shot turbines project metal abrasive onto the surfaces, ensuring thorough cleaning in a single cycle. The portable movable shot blasting machine, driven by the features of a walking motor for independent movement for the surface of plates.

To eliminate residual shot-abrasive from the sheet materials, a rotate-sweep-brushing system and air-blowing mechanism with a blow-off fan are installed at the roller conveyor’s exit side.

Standard equipment includes a Programmable Logic Controller (PLC), Human Machine Interface (HMI) display, automatic shot-wheel startup, working hours time counter, and a variable frequency drive (VFD) for the roller conveyor, among other features.