Sand blasting machine for cylinder inner surface is specifically designed for effectively treating the internal surfaces of LPG cylinders, including new or refurbished gas bottles, boilers, fire extinguishers, and various cylindrical items. LPG gas bottle cylinder internal-surface shot blasting machine is also suitable for other short or medium-length hollow products of different dimensions.

The LPG cylinder bottle inner-surface shot blasting machine seamlessly integrates into a fully automatic process by incorporating loading and unloading equipment powered by electricity or hydraulic mechanisms. Loaders are commonly utilized for heavier workloads, efficiently discharging items into a pneumatic or hydraulic conveyor system.

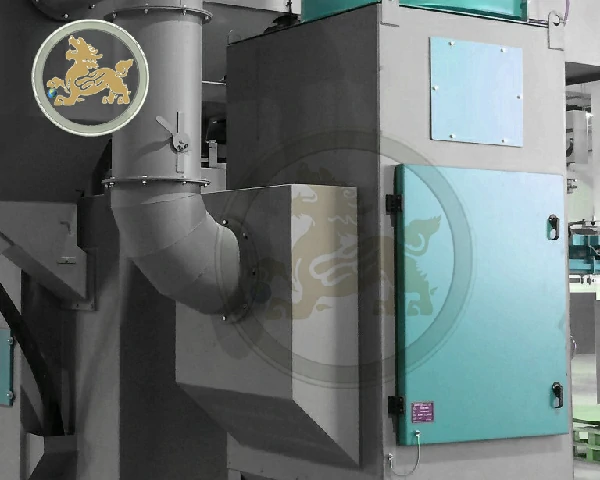

Elevator: The elevator raises the abrasive to the separator, utilizing a bucket made of foundry casting, while a tension device prevents belt slippage.;

Separator: The separator incorporates DISA & Pangborn technology, enabling the separation of abrasive into three classes with an impressive efficiency rate of 99.5%;

Cartridge filter: The dust collector filters utilize a cartridge-type system, boasting an exceptional efficiency rate of 99.9% and offering hassle-free replacement of cartridge filters;

Noise: Silencer to minimize of noise reach of 90dB;

Electrical elements: All voltage adopts, overload protection on all motors, PLC automatic control & HMI (Human Machiner Interface) to monitor all elements;

Safety: The operation features a safety interlock system, while the control cabinet is protected with IP65 rating;