Shot blasting machine, Shot-peening machine

Functions of the Shot blasting machine:

Sino-Abrator specializes in manufacturing highly specialized shot blasting machine and sand blasting machines that incorporate cutting-edge turbine-wheel technology. These machines are widely utilized for treating metallic and stone surfaces with exceptional efficiency and performance.

The primary purpose of shot blasting includes the removal of rust, scales, sand, and burrs from workpieces. Additionally, it offers various other benefits such as enhancing anti-fatigue properties, prolonging surface lifespan through hardening (known as shot-peening), providing a finishing blast for delicate parts, and preparing surfaces for coating or painting by creating a roughened texture.

Surface cleaning:

Shot blast equipment finds its initial application in the foundry industry, where it effectively eliminates sticky sand and oxide scale from the surfaces of steel and iron castings. This preparatory process is indispensable before conducting quality inspections on the castings.

Workpiece strengthening:

Based on modern metal strength theory, the primary approach to enhancing metal strength involves increasing dislocation stress within the material.

Models of the Shot Blast Machines:

Applications of the Shot Blast Machines:

- Foundry and Forge industries: the shot blasting equipment mainly for the de-sanding, deburring of refreshing surface, detect of the defect of casting parts. Tumble blasting machine, Rotary-table blasting machine, rolling drum shot blast machine;

- Steel plate industry: The steel plate will have some burrs, which will affect the appearance of the steel, or the rust expose after the rain, can choose of the roller type steel plate pretreatment line.

- For beams, profiles: large size, high quality, high corrosion-resistant flat steel and large angle steel with unequal sides and thickness, use the roller type shot blast machine to ensure no longer have dead-angles.

- Hardware industry: In the hardware industry, there are a large number of parts and many types. Most parts need to clean, smooth, and flat on the surface. Generally, hook type or crawler shot blast machines.

- Automobile industry: Many parts in the automotive industry need derust and polish. The shot blasting machine can achieve rust removal and polishing without affecting the shape and material strength. The shot blast machine and sandblasting room is a welcome method.

- Bearing and mold industry: The bearing and mold industry has high surface requirements to remove various burrs, impurities, etc.; recommend the rotary table shot blast machine.

- Valve factory: All kinds of valves are basically castings, suitable for crawler shot blast machine, which can clean 600-1000kg at one time.

- LPG gas tank: use the hook-through type and the special steel cylinder shot blast machine, which has high efficiency and a good cleaning effect.

Advantages of the Shot Blast Machines:

The Shot Blast Machine combines automatic processing with manual assistance, saving time and allowing for the reuse of shot abrasives, making it a cost-effective and efficient surface cleaning method.

Shot blasting & sand blasting versitilly to use various types of shot abrasives, such as glass beads, steel shots, and steel grit, tailored to different surface grades and materials, making it the preferred method for surface cleaning, smooth and uniform surface finish without causing any damage.

The Shot Blast Machine effectively prepares surfaces for coating or painting applications.

Furthermore, it is an environmentally friendly alternative to sandblasting as it doesn’t generate pollution.

Efficient of the Shot Blasting Machines:

Cement, Marble, Tile surface: Achieves work efficiency of 200-400 square meters per hour.

Steel plate works: Suitable for steel quality grades SA 2.5 to SA 3. Speed for SA 2.5 is approximately 4m/min, and for SA 3 it’s around 3m/min. Processing area per hour: SA 2.5 covers about 75-100 square meters.

Factors that affect the Shot Blasting process and effectiveness:

- Surface condition: Assess the general state of the metal surface that requires cleaning, such as rust, sand, burrs, etc.

- Material, size, and shape: Consider the composition, dimensions, and geometry of the metal parts, including the presence of potential dead angles.

- Shot-abrasive properties: Consider the hardness, size, and material of the shot-abrasive used for surface treatment.

- Shot wheel turbine: Evaluate the velocity, shot projectile capacity, and angle of the shot wheel turbine.

- Machine working condition: Assess the overall working condition and performance of the shot blasting machine.

- Post-cleaning processes: If there are subsequent processes like coating or painting, ensure that the cleaning speed remains consistent to maintain efficiency and quality.

- Important to consider environmental protection measures throughout the shot blasting process to minimize any potential impact on the environment.

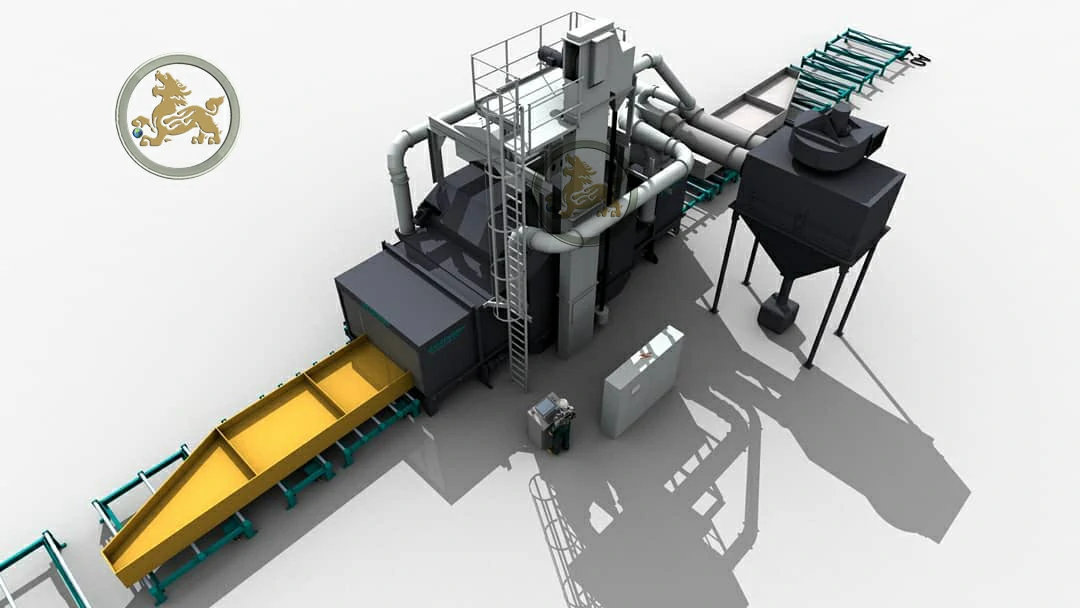

Main structure of the Shot Blasting Machines:

Airless Shot Wheel Turbines:

Shot turbines: Variable from 2200 to 3800 RPM for maximum abrasive velocity fitted with optional electronic inverter control; Upgraded wearing-resistance protective liners with low working noise & vibration;

Blade: Cast from unique wearing resistant alloy for extensive life with access design for easy change;

Conveying system:

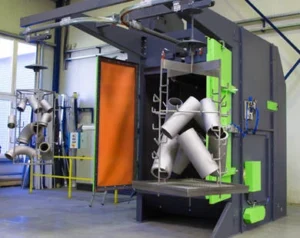

- Hook-type blasting equipment: Designed with one or multiple hooks, this equipment allows for manual loading, making it suitable for small, medium, and large-sized workpieces.

- Roller-type shot blasting equipment: The rollers inside the blasting cabinet are safeguarded by a special alloy jacket, ensuring a lifespan of over 4,000 hours. The cleaning speed is controlled by motors with an inverter-driven conveyor system.

- Tumble-type shot blasting equipment: Equipped with an endless rotating rubber belt, this equipment facilitates the tumbling of workpieces within the blasting cabinet.

- Rotary table & Rolling drum type shot blasting machine: The table and drum are constructed from wear-resistant casting liners, significantly extending their durability.

Additional media-remove system:

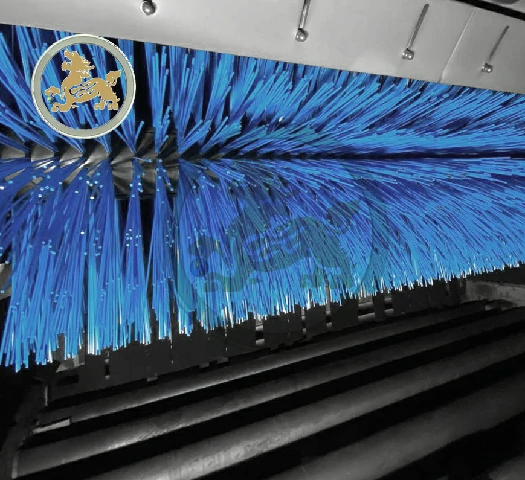

Scrapper system: Scrappers’ height adjust with the PLC and HMI interlock control;

Brush sweeping system: The continuous brush sweeping, made of high-performance Nylon, can be adjusted in height based on the sheet’s requirements;

Fan blowing system: The blowing-off station features a high-pressure fan, and the direction of the blowing nozzle can be adjusted as needed.

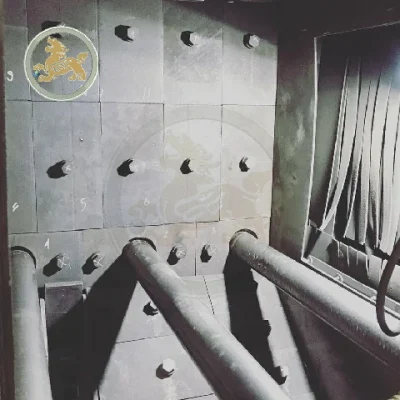

Durable Shot Blasting Chamber:

Shot blasting room: The shot blasting room is designed using CAD to achieve optimal blasting angles and distances. It is constructed with durable profiles and 10mm plates, while the direct-blasting hot area utilizes upgraded manganese casting steel with 35-45 HRC for enhanced wearing resistance.

Entrance/Exit: The input and output areas are sealed with rubber bands, and a labyrinth structure is implemented to prevent abrasive leakage.

Recycle of abrasive material:

Screw conveyor: utilizes 16Mn material for the spiral blade parts, which are assembled at the end of the screw shaft. It efficiently conveys the shot abrasive to the elevator, which is driven by a cycloid pin gear reducer.

Elevator: The elevator raises the abrasive to the separator, utilizing a bucket made of foundry casting, while a tension device prevents belt slippage.;

Separator: The separator incorporates DISA & Pangborn technology, enabling the separation of abrasive into three classes with an impressive efficiency rate of 99.5%;

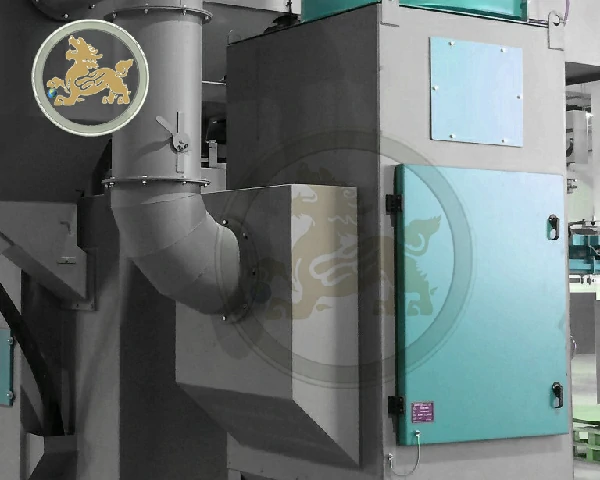

Dust collect system:

Cartridge filter: The dust collector filters utilize a cartridge-type system, boasting an exceptional efficiency rate of 99.9% and offering hassle-free replacement of cartridge filters;

Noise: Silencer to minimize of noise reach of 90dB;

Electrical Control system:

Electrical elements: All voltage adopts, overload protection on all motors, HMI (Human Machiner Interface) to monitor all elements;

Safety: The operation features a safety interlock system, while the control cabinet is protected with IP65 rating;

Best manufacture of the Shot Blasting Machines:

The Sino wheelAbrator professionals design, technical supporting, manufactures and services shot blasting machine and surface preparation machines and related blasting products for a range of industries, cleaning, derusting, descaling and hardening of surfaces. Improvements can be realized by upgrading to newer technology.

We provide world-class shot blasting machines & granalladora along with new innovative ideas and concepts to eliminate old design problems with shot blasting equipment.