No. 1 of completely Shot Blasting Machine guideline

Functions of the Shot blast machines:

Sino-Abrator specializes in the development of advanced shot blast machines and sand blasting machines, utilizing cutting-edge technologies to deliver efficient and high-performance solutions. The turbine-wheel shot blast machine guideline, a prominent offering, finds extensive application in treating metallic and stone surfaces.

The primary purposes of shot blasting encompass various tasks such as de-rusting, descaling, de-sanding, and deburring of workpieces. Additionally, shot blasting serves other crucial functions such as improving anti-fatigue properties, surface hardening for enhanced lifespan (known as shot-peening), precision blasting of delicate parts, and surface roughening to prepare for coating or painting processes.

Surface cleaning:

Shot blast equipment plays a vital role in the foundry industry, effectively removing stubborn sand and oxide scale from the surfaces of steel and iron castings. This preparatory process is indispensable before conducting quality inspections on castings.

Workpiece strengthening:

In accordance with modern metal strength theories, increasing dislocation stress within the metal is a key approach to enhancing its strength. Shot blasting contributes to this goal by inducing controlled dislocation stress, resulting in strengthened workpieces with improved mechanical properties.

Two different techniques: Shot blasting & Sandblasting:

Shot Blasting:

The shot blasting machine utilizes centrifugal rotating turbine blades to propel high-speed steel media (such as steel, copper, aluminum, or other high-velocity beads) onto the surface at a specific angle. This process serves multiple purposes, including deburring, desanding, cleaning, and strengthening the surface of castings, as well as removing rust, paint, or other coatings.

The selection of abrasive media for shot blasting depends on the particular task at hand. In most cases, metallic materials are the preferred choice due to their effectiveness and versatility in achieving the desired results.

SandBlasting:

The sandblasting process involves the pneumatic acceleration of the media using compressed air, eliminating the need for a centrifugal turbine. This allows users to exert control over the blast direction through a specially designed nozzle.

In certain specialized applications, a wet blasting machine is employed, where an abrasive media-water mixture is utilized. This mixture enhances the efficiency of the sandblasting process, albeit at an increased cost.

For most cases, dry or free-flowing abrasive media is consumed during the sandblasting operation. This ensures optimal efficiency while minimizing expenses.

Different from shotblasting and shot-peening:

Shot blasting machine primarily serves as a surface finishing process, aiming to modify parts’ surfaces by smoothing rough areas, reshaping contours, or removing contaminants. Its main purpose is to prepare the surface for subsequent operations, such as painting or coating, to improve adhesion and smoothness.

Shot-peening machine focus on the process of “peening.” This technique is aimed at improving the material properties of the surface by increasing compressive stress. The primary objective of shot peening is to enhance the workpiece’s strength and durability by mitigating tensile stress and improving resistance to fatigue and cracking.

Applications of the Shot Blast Machines:

- Foundry and Forge industries: Shot blasting equipment is primarily used for de-sanding, deburring, and refreshing the surfaces of casting parts. This includes the use of tumble blasting machines, rotary-table blasting machines, and rolling drum shot blast machines.

- Steel plate industry: To address burrs and rust on steel plates, the roller type steel plate pretreatment line is commonly utilized which ensures a clean and smooth surface, enhancing the appearance and performance of the steel plates.

- Beams and profiles: For large-size, high-quality steel components like beams and profiles, the roller type shot blast machine is utilized. This machine eliminates dead angles and provides comprehensive surface treatment to meet corrosion resistance requirements.

- Hardware industry: In the hardware industry, parts often require cleaning, smoothing, and achieving flat surfaces. The preferred shot blast machines for this purpose are the hook type or crawler shot blast machines, which effectively clean and create smooth surfaces on hardware components.

- Automobile industry: Shot blasting machines play a crucial role in the automobile industry by facilitating rust removal and polishing of various parts. They provide efficient cleaning and polishing without compromising the shape or material strength of the components. Both shot blast machines and sandblasting rooms are commonly used.

- Bearing and mold industry: The bearing and mold industry places high importance on surface quality, necessitating the removal of burrs and impurities. The rotary table shot blast machine is recommended for effective cleaning and preparation of bearings and molds.

- Valve factory: Valves, being primarily castings, benefit from the use of crawler shot blast machines. These machines can handle significant loads, efficiently cleaning and preparing valves for further processing.

- LPG gas tank: For LPG gas tanks, the hook-through type and special steel cylinder shot blast machine are utilized. These machines offer high efficiency and deliver excellent cleaning results, ensuring the gas tanks are thoroughly cleaned and ready for use.

Advantages of the Shot Blast Machines:

Time-efficient and cost-effective: The Shot Blast Machine’s automated process, aided by manual assistance, saves time, and reusing shot abrasives makes it an economical surface cleaning method.

Versatile shot abrasives: It accommodates various shot abrasives like glass beads, steel shots, and steel grit, enabling customized cleaning and surface finishing for different materials and surface grades.

Effective surface preparation: The machine readies surfaces for coating or painting, ensuring optimal adhesion and a successful outcome.

Eco-friendly: Unlike sandblasting, it generates no pollution during surface cleaning, making it an environmentally sound choice.

Superior surface quality: It delivers a flawless, homogeneous finish while safeguarding surfaces, ensuring high-quality results.

Efficient of the Shot Blasting Machines:

Cement/Marble surface:

The Shot Blast Machine offers efficient work capabilities on cement surfaces, achieving a productivity rate of 200-400 square meters per hour. This translates to a swift and effective treatment process, optimizing time and resources.

Working on steel plates:

For steel plates, the Shot Blast Machine demonstrates impressive performance across different steel quality grades, ranging from SA 2.5 to SA 3. The processing speed varies depending on the grade, with approximately 4 meters per minute for SA 2.5 and approximately 3 meters per minute for SA 3. As a result, the machine can process a considerable area per hour, ranging from 75-100 square meters for SA 2.5 surfaces.

The type of shot abrasive media:

- Steel grit

- Copper shot

- Zinc shot

- Cut wire shot

- Steel cut wire

- Aluminum oxide

- Steel pellets

Factors that affect the Shot Blasting process and effectiveness:

- Surface condition: Assess the overall condition of the metal surface, including the presence of contaminants such as rust, sand, or burrs that need to be removed.

- Material, size, and shape of the metal parts: Consider the material composition, size, and shape of the metal parts, including the presence of hard-to-reach areas or dead angles that require special attention during the cleaning process.

- Shot abrasive properties: Determine the hardness, size, and material of the shot abrasive to be used for treating the surface. These properties should be selected based on the specific cleaning requirements and the compatibility with the metal surface.

- Shot blasting machine parameters: Adjust the velocity, shot projectile capacity, and angle of the shot wheel turbine in the shot blasting machine to optimize cleaning efficiency and effectiveness.

- Shot blasting machine condition: Ensure the shot blasting machine is in proper working condition through regular maintenance and inspections. This ensures consistent and reliable cleaning performance.

- Subsequent processes (e.g., coating, painting): Consider any subsequent processes, such as coating or painting, and ensure that the cleaning method aligns with these processes. Consistency in cleaning speed is particularly important when performed on the same production line as subsequent processes.

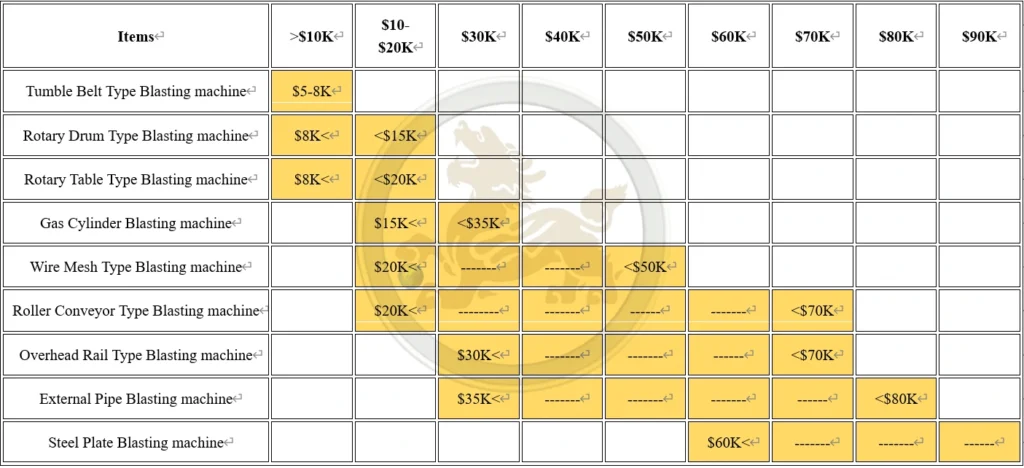

The cost of a shot blaster?

Please consult the guideline chart from Wheelabrator for purchasing a shot blasting machine. Review and compare it with your sourcing budget. However, keep in mind that the provided cost is for informational purposes only. The specific purpose and workload will determine variations in shot wheels, motor, quantity, brand, and automation level. For a confirmed final cost, please contact us directly.

Shot Blasting Machines maintenance:

Before each shift, diligently review the daily work diary to verify the operational status of the shot blasting machine. Ensure a well-organized work environment with clearly assigned responsibilities and accessible records.

Upon completing daily tasks, promptly clean up scattered steel abrasive and ensure the power and air supply are disconnected.

Before conducting maintenance, always disconnect the power supply and prominently display a clear “Maintenance in Progress” sign. For internal inspection or repairs, set up a conspicuous notice board and ensure the equipment is safely controlled and supervised.

Refer to additional information for details on daily, weekly, monthly, quarterly, and annual maintenance of the shot blasting machine.

Best manufacture of the Shot Blasting Machines:

Sino wheelAbrator specializes in the design, technical support, manufacturing, and servicing of shot blasting machines and surface preparation equipment for diverse industries. Our solutions encompass surface cleaning, derusting, descaling, and surface hardening.

Upgrading to advanced technology offers significant improvements. Count on us for top-tier shot blasting machines, granalladoras, and groundbreaking ideas that address and resolve design issues in shot blasting equipment.