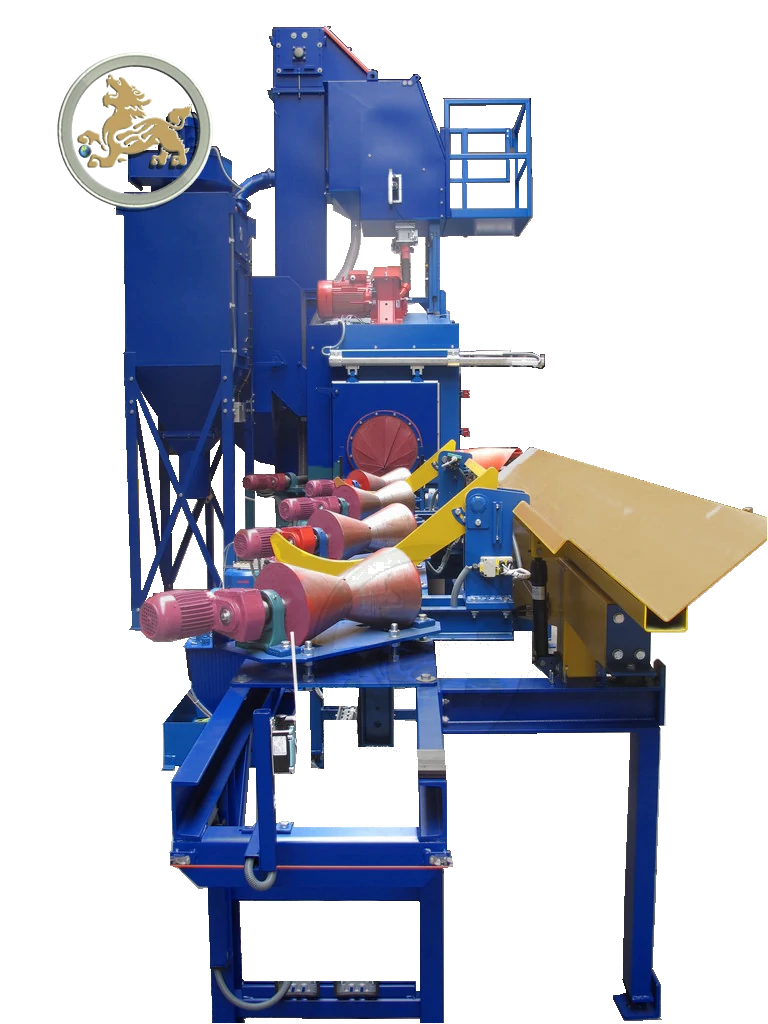

Shot blasting machine for pipes is prepare internal & external surfaces of pipes, tubes, round bars, gas steel bottles, and cylindrical elements. The tube shot blasting machine treats various diameters & lengths at different transport speeds in a continuous process.

With a pass-through arrangement, these shot blasting machines for tubes’ external & internal surface, feature a motor-variable-frequency-driven inverted shot blasting system on a conical cylindrical conveyor or a skip rotating conveyor with longitudinal axis rollers, which ensures a uniformly blasted surface.

These automatic continuous shot blasting machines can operate independently or be integrated into existing transport systems for highly productive lines, including paint application, drying chambers, automatic painting chambers, and drying tunnels.

Standard shot blast equipment includes PLC, HMI display, automatic or manual modes, automatic shot wheel turbine startup, working-hour time counter, and variable frequency drive (VFD) for roller or skip conveying system.