Sand casting Molding Line

SAND CASTING LINE

SAND CASTING EQUIPMENTS

Sand casting is widely used metal casting technique that employs sand as a mold material. Its enduring popularity stems from low overhead costs and the ability to cast nearly any metal into various shapes and sizes. The sand molding process involves transferring molten metal into a sand mold, where it solidifies into the desired form.

The green sand casting and resin sand molding have improved the efficiency of creating expandable sand molds, making sand casting even more effective. Approximately 75% of copper alloys, stainless steel, aluminum alloys, and cast irons etc.,. The flexibility of sand significantly reduces operating costs, making it an attractive choice for manufacturers. Good quality casting sand enhances results, ensuring the final product aligns with the original design.

Resin sand molding line

Core Shooting Machine

A core shooter rapidly injects core sand into a core box, causing the compressed air inside to expand and compact the mold material. This process can accommodate both damp and dry materials in hot or cold core boxes. In a typical cold-box setup, prepared mold material is shot into a hydraulically clamped core box, preventing movement during filling and hardening. After shooting, the hardening device activates, allowing the core to set. Proper ventilation is crucial, with vents covering 3 to 5% of the box surface to facilitate even gas penetration and swift hardening.

Resin sand mixer

The jolting squeeze molding machine is user-friendly and low-maintenance, making it a standard choice for green sand foundries seeking efficiency in jobbing and production. This green sand molding machine features reliable pre-jolt and a simultaneous jolt and squeeze process, resulting in harder, more uniform molds.

Green sand molding line

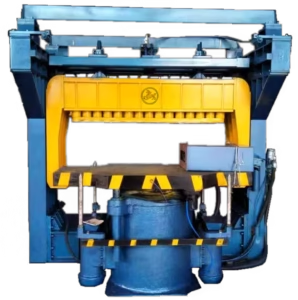

Jolting Squeeze Molding Machine

The jolting squeeze molding machine is user-friendly and low-maintenance, making it a standard choice for green sand foundries seeking efficiency in jobbing and production. This green sand molding machine features reliable pre-jolt and a simultaneous jolt and squeeze process, resulting in harder, more uniform molds.

Green Sand Mixer

The green sand mixer is essential for achieving optimal molding sand parameters, serving as the core of the sand-making plant. In small to medium-sized systems, versatility is crucial. Designed for maximum performance and energy efficiency, these mixers have capacities ranging from 50 kg to 5000 kg.

Dust Collector

Dust collector is essential in abrasive blasting processes, which involve propelling abrasive media at high speeds to clean or finish surfaces. This method generates significant amounts of harmful dust, making effective dust collection critical for protecting worker health and safety. Our advanced dust collectors utilize bags and cartridge filtration technology to capture particles as small as 0.5 microns, ensuring compliance with strict emission standards.